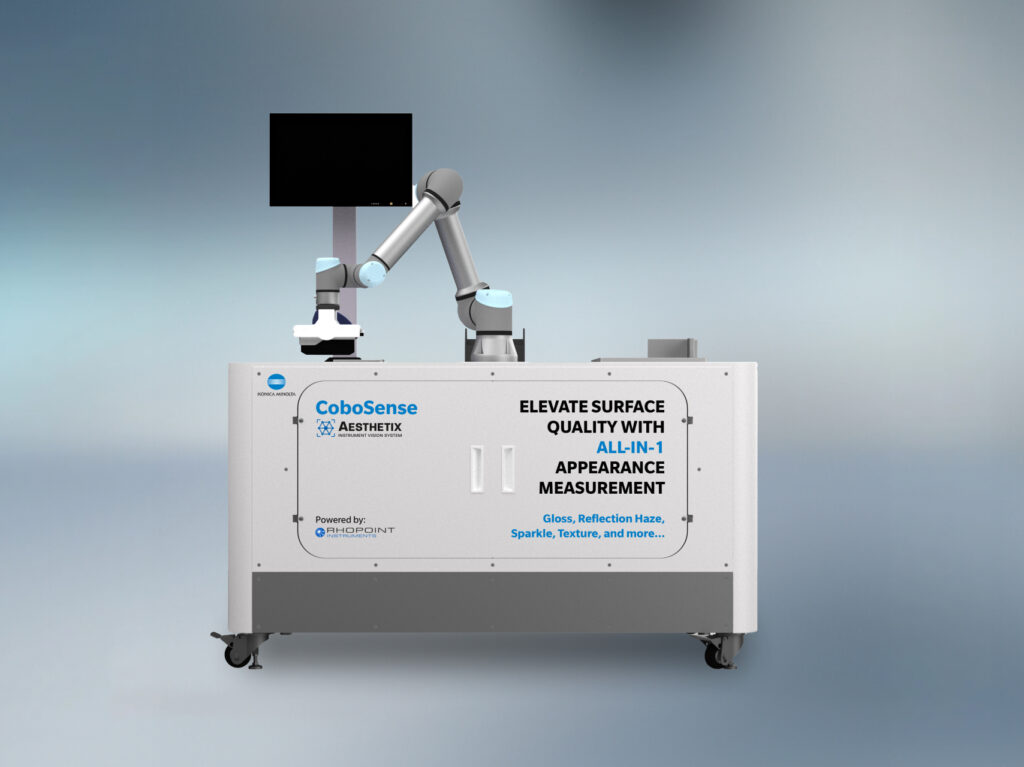

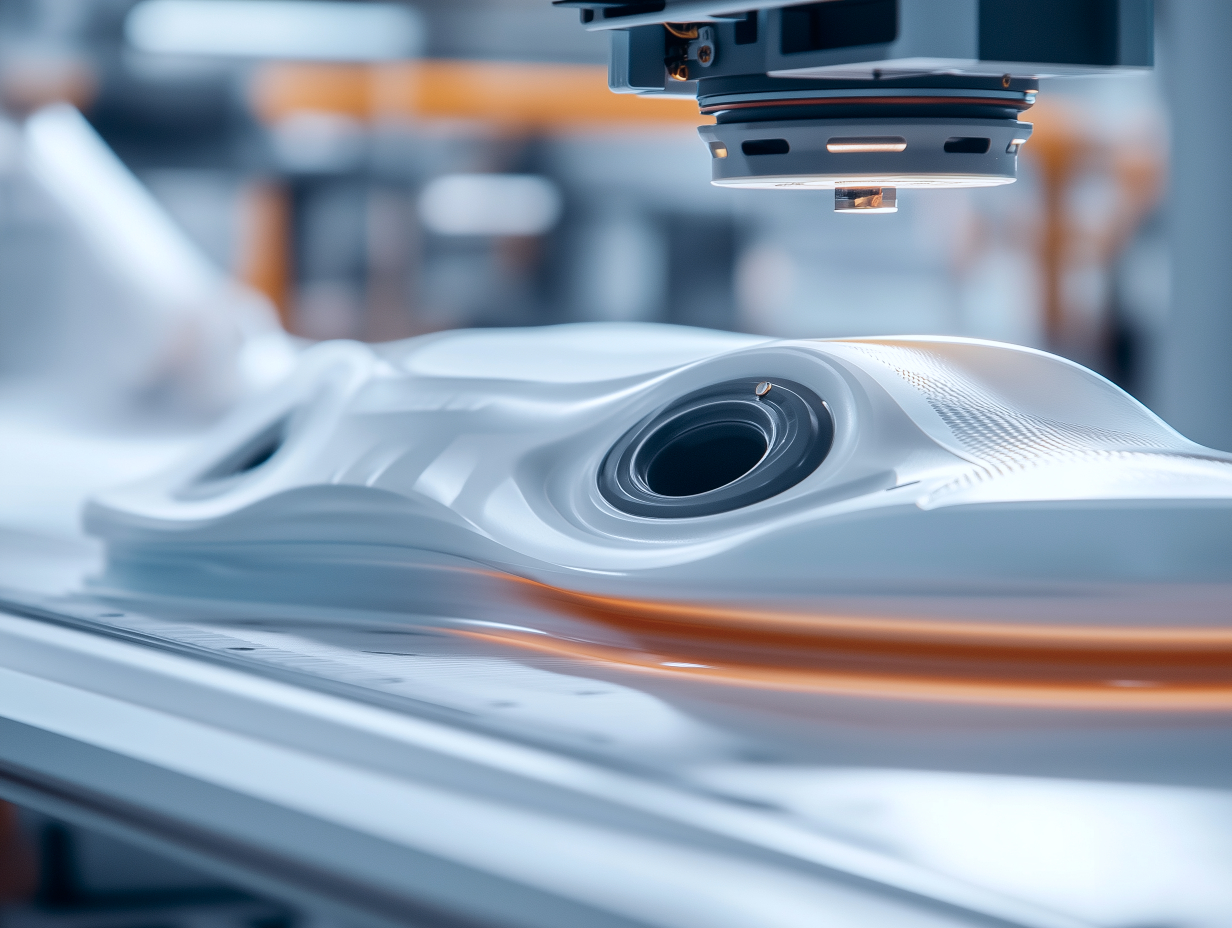

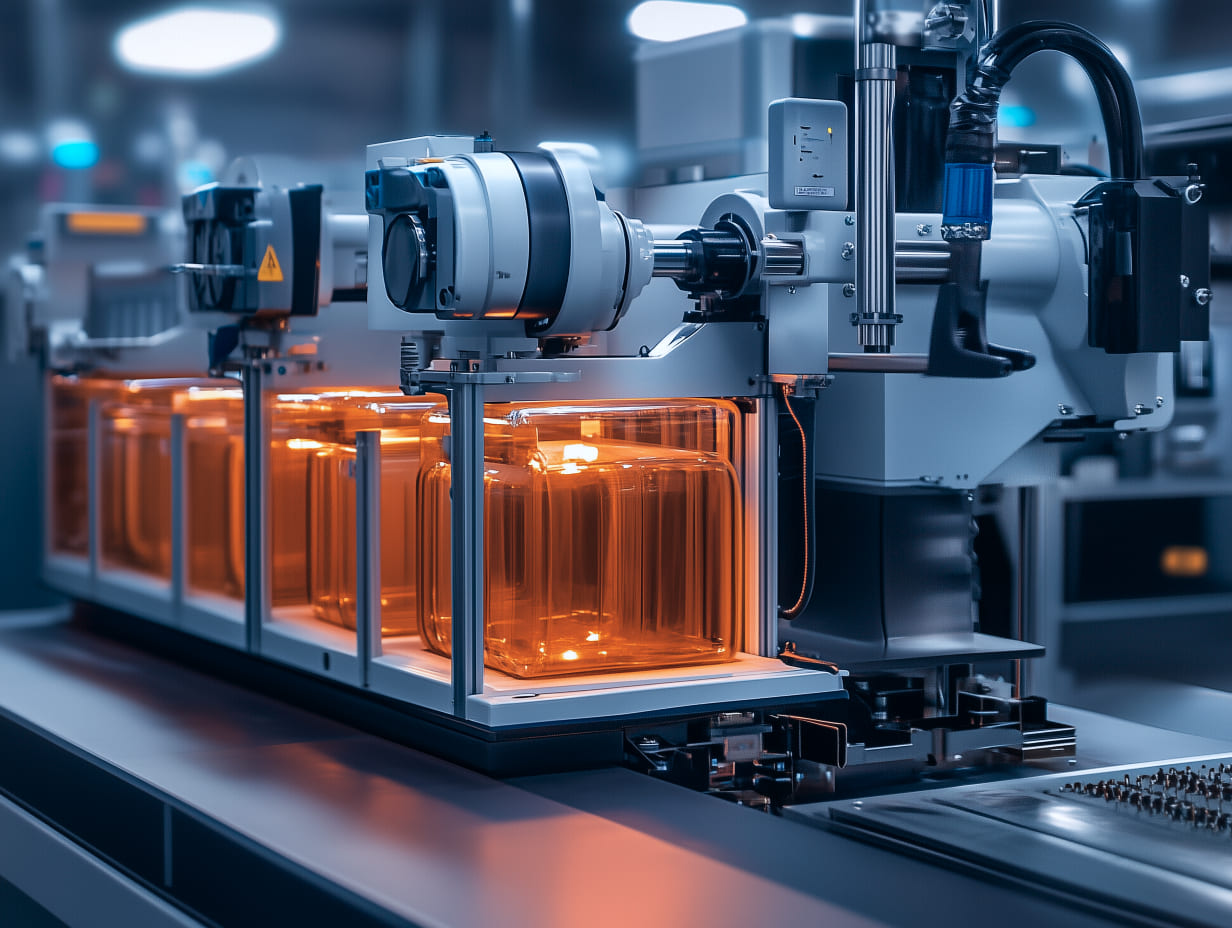

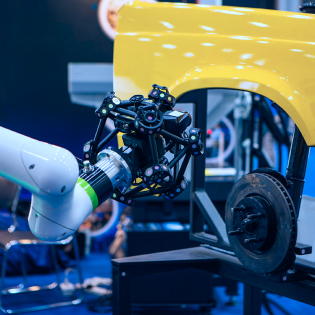

Automates Surface Measurement and Analysis

With its all-in-one measurement suite and built-in software, CoboSense-Aesthetix streamlines inspection workflows, reducing variability and human error while ensuring consistent, data-driven material analysis.