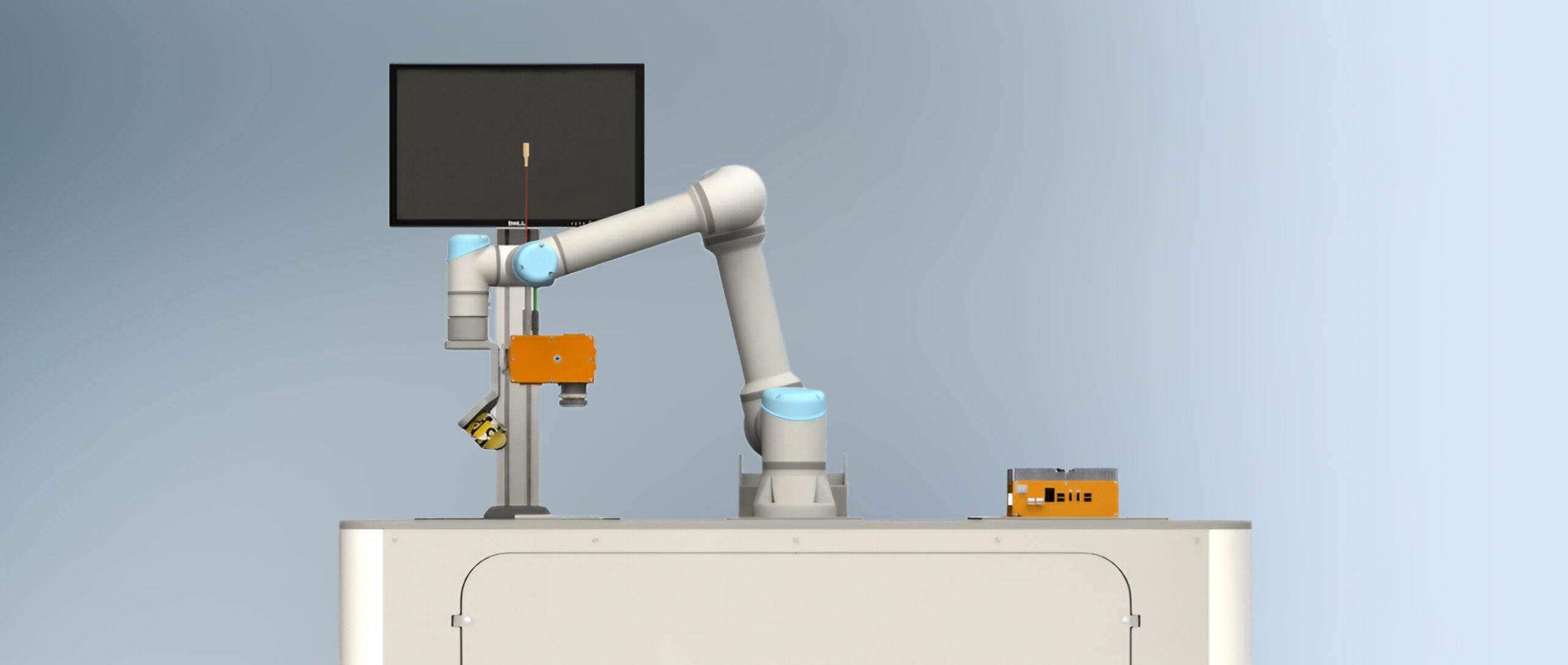

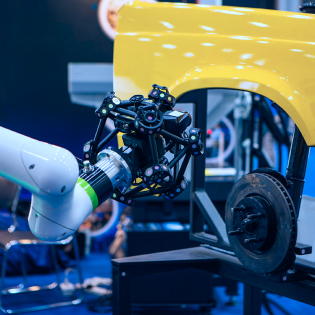

Performs Non-Destructive, Real-Time Analysis

Conduct thorough inspections without damaging the product. The hyperspectral imaging technology allows for real-time data acquisition and analysis, providing immediate feedback for prompt adjustments to the production process. The result: more efficient quality control and reduced material waste.