Automate Material Movements

Eliminate manual labor and associated risks with our autonomous mobile robots for efficient transportation and material handling across warehouses, manufacturing facilities, and logistics hubs.

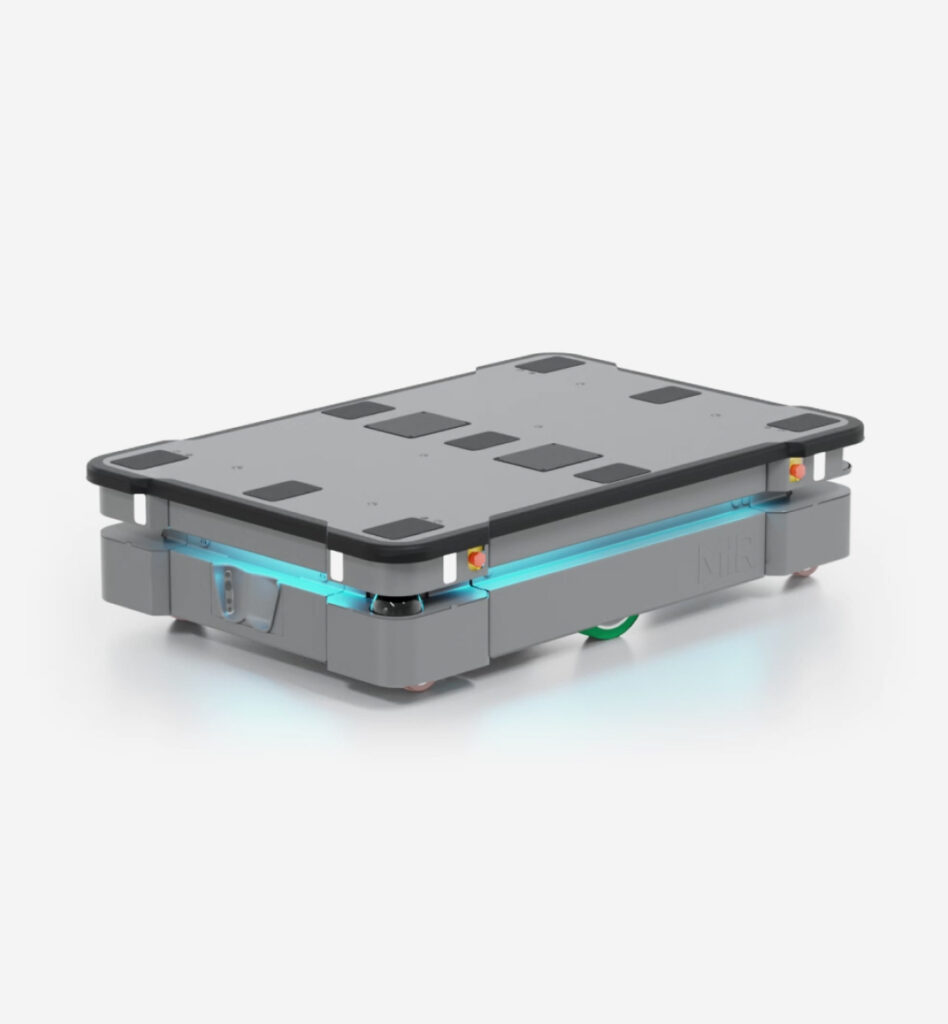

The MiR250 has a footprint of just 58 x 80 cm and is only 30 cm high. Its compact size allows it to navigate through spaces as narrow as 80cm. It can handle a load of up to 250 kg, and can move at a max speed of 2 m/s. It can be customized with top modules such as racks and lifts. MiR250 is equipped with two safety laser scanners, two 3D cameras, and eight proximity sensors to ensure safe autonomous navigation.

The MiR600 is equipped with a pallet lift and can autonomously pick up, transport and deliver pallets throughout your facility. It has a 600 kg payload and can move at a max speed of 2 m/s. It can safely maneuver in crowded surroundings thanks to the 360 degree view from the safety laser scanners. The MiR600 and the MiR1350 are the first IP52-rated AMRs in the market that can withstand dust particles and water drops in more challenging environments.

The MiR1350 is equipped with 360° laser-scanner technology, allowing it to see 360 degrees around itself. For additional safety, it has 8 proximity cameras that allow it to detect objects below the safety laser-scanners’ plane of view. It complies with the highest available robot standards and has 13 TÜV certified safety features. It has a 1350 kg payload and excels in heavy load and pallet transportation, eliminating the need for traditional forklifts.

sConnect is a one-stop analytics solution that gives you actionable insights to improve AMR performance. The intuitive dashboard is user-friendly and easy-to-understand with colour displays, charts and graphs that help managers identify bottlenecks and their root causes. Get real-time performance monitoring with the Overall Robotic Effectiveness (ORE) metric.

sWorkflow is a dynamic software-based solution that allows AMRs to communicate with other material handling equipment and IoT sensors. This software allows you to make real-time changes to missions and monitor and optimise workflows across various stages of inventory management and movement. Integrate sWorkflow with analytics software and get real-time data and actionable insights.

sInfra is a lift accessibility module (LAM) that integrates with the OEMs lift system, occupancy monitoring system (OMS), and the AMR fleet. This capability allows the AMRs to autonomously transport loads to different floors. The OMS uses a camera and a detection algorithm to monitor the occupancy status of the lift so that humans and AMRs can safely use the lift at the same time.

sLatch is a modular latching solution designed to operate in tandem with the MiR100 and MiR250. It engages with trolley systems without the need for docking stations. The AMR automatically engages, transports and disengages without any human intervention. The sLatch allows your AMR to transport high payloads through tight and narrow spaces.

It all depends on how big the project is. The time it takes will depend on how many robots you need, how many workflows must be set up and how many accessories are included. Evaluating the facility is crucial for setting up the solution. An equally important part of the implementation is staff training. For many workers, collaborating with a robot is new, and they need to understand how to work in the presence of a moving object. Although the robots are very safe and reliable, proper orientation is essential. A simple setup of one robot to handle multiple workflows typically takes two to four days, including staff training.

Yes, they can, but a thorough and detailed analysis must be conducted before any integration.

We strongly recommend that all staff members sharing the workspace with the robot complete training.

The training primarily focuses on safety and coexisting with the robot and takes approximately 1 hour.

For technicians responsible for the robot, the training can take 2–3 days. It covers how to set up the robot, run basic missions, configure the robot’s work map, and establish simple workflows. Each training session is tailored to the specific needs of the customer and is proposed after evaluating the facility.

AMRs are designed to operate safely in dynamic environments. They use advanced sensors and algorithms to navigate autonomously, avoiding obstacles and ensuring safety. They adhere to safety standards like ISO 3691-4, featuring collision avoidance systems, emergency stop capabilities, and safe speed controls to minimize risks in mixed human-robot environments.

Autonomous material handling involves AMRs that use onboard intelligence to navigate and adapt in real-time to their surroundings without pre-set paths. Automated material handling, such as with AGVs, relies on fixed routes and external guidance systems, like wires or magnets, to move goods, making them suitable for stable, controlled environments.

AGVs are vehicles that follow fixed routes using embedded guides such as wires or magnets to transport materials. They are commonly used in manufacturing and warehouse settings to move goods along predetermined paths. AGVs are ideal for repetitive, predictable transport tasks in controlled environments.