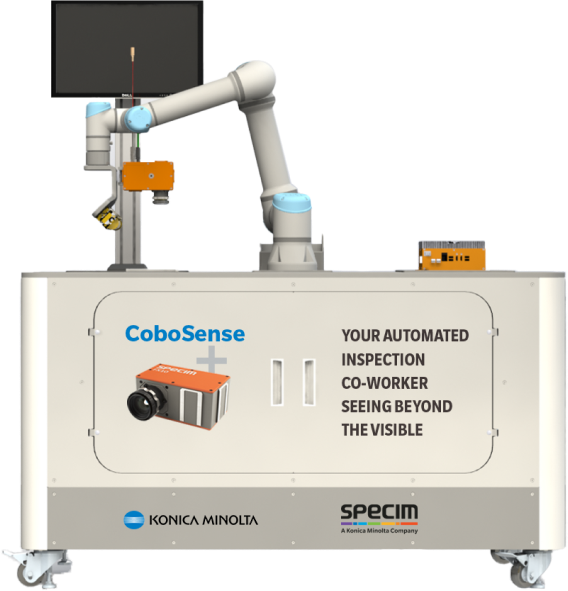

Boost Efficiency

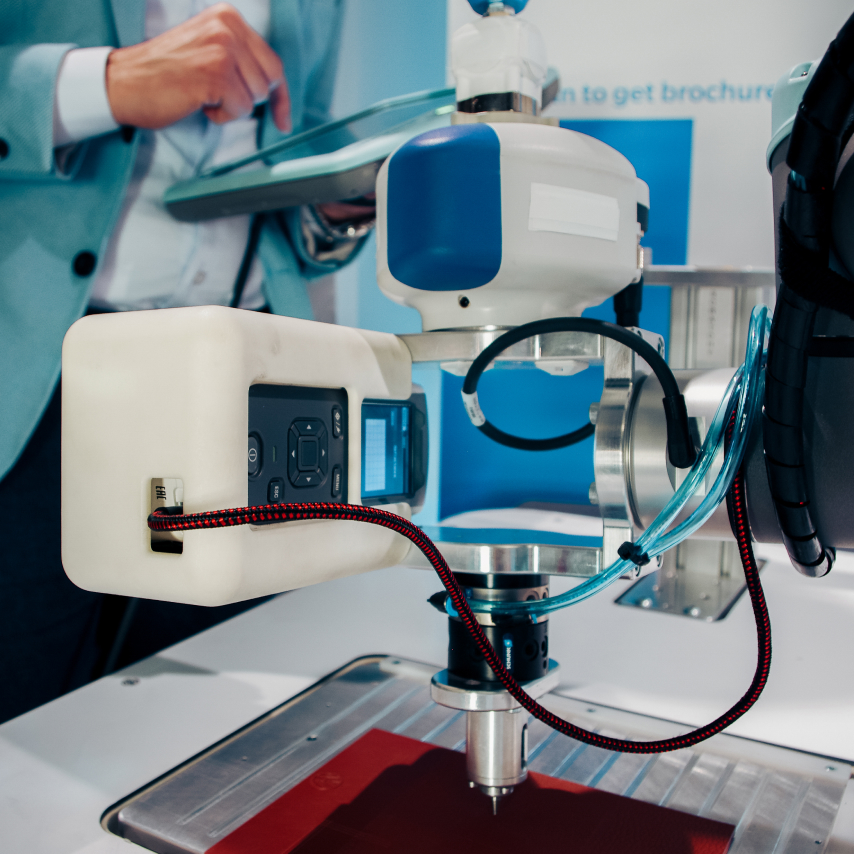

CoboSense improves cost and production efficiency by automating the visual inspection workflows, ensuring high-quality output with minimal supervision.

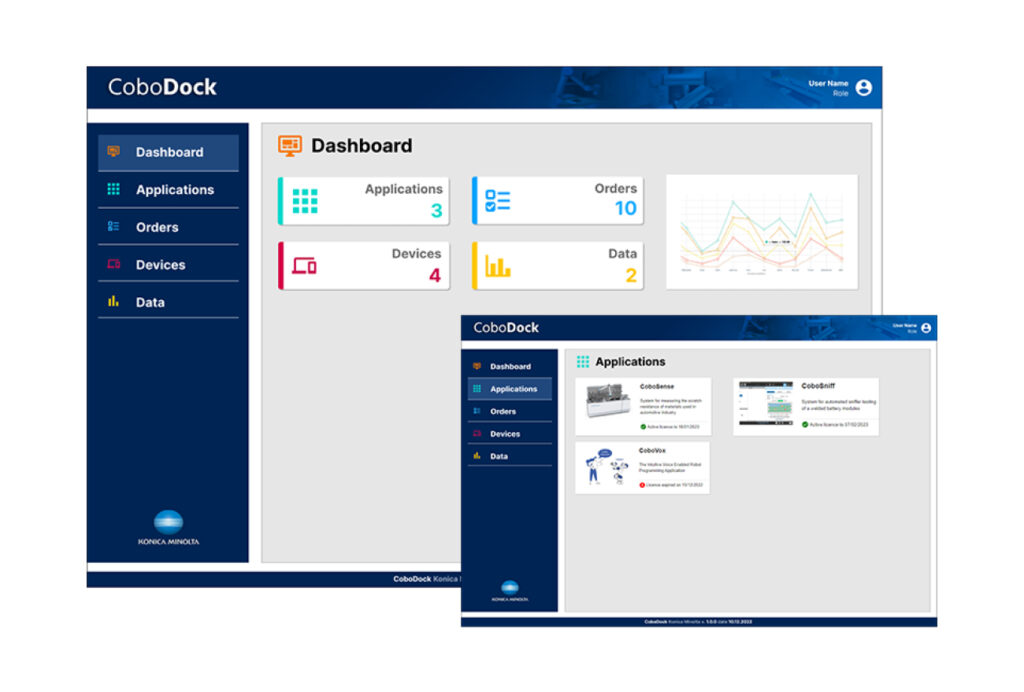

Learning to operate CoboSense is fairly straightforward. Operators can quickly learn the basic setup and functionalities in just a few days, ensuring seamless integration into your production line with minimal downtime.

CoboSense comes with a comprehensive one-year warranty. After the initial warranty period, customers can opt for a service-level agreement (SLA) tailored to their needs to continue receiving support and maintenance services.

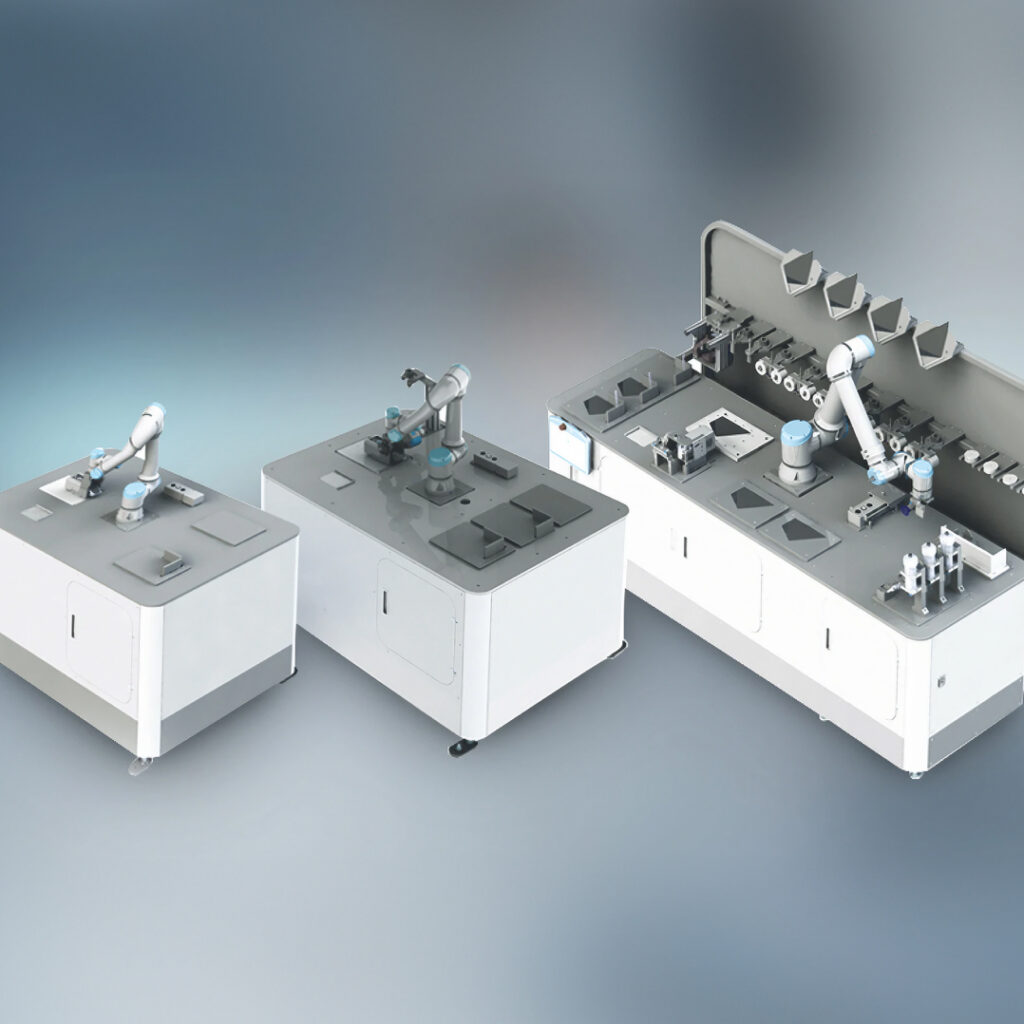

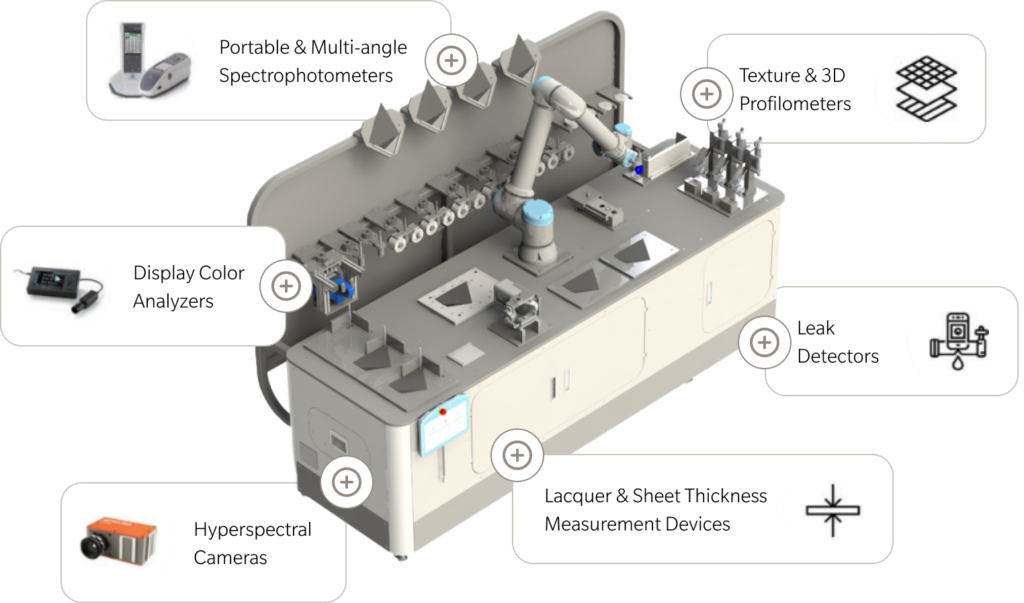

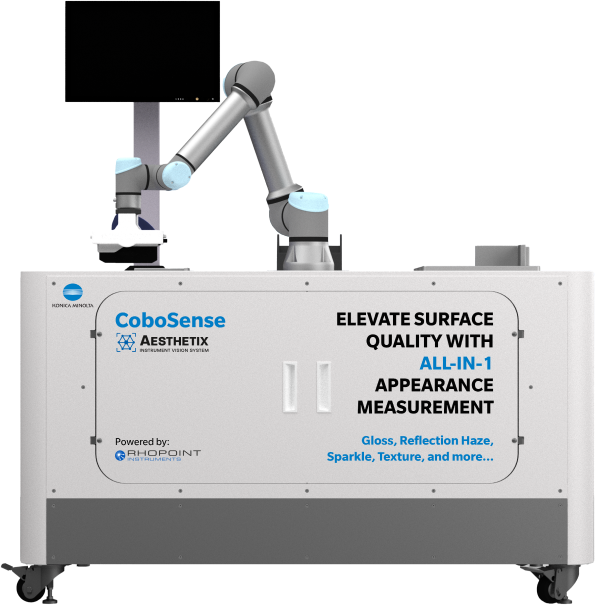

The standard CoboSense setup includes:

No programming skills are required to operate CoboSense. Operators simply need to familiarize themselves with its user-friendly interface, which is designed for ease of use with minimal controls.

Absolutely. CoboSense is highly adaptable, designed to meet specific industry standards, and expand based on customer needs. This flexibility ensures that our surface inspection system remains applicable and valuable as your quality control requirements evolve.