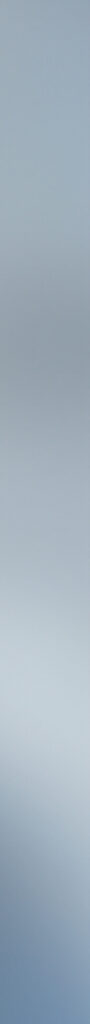

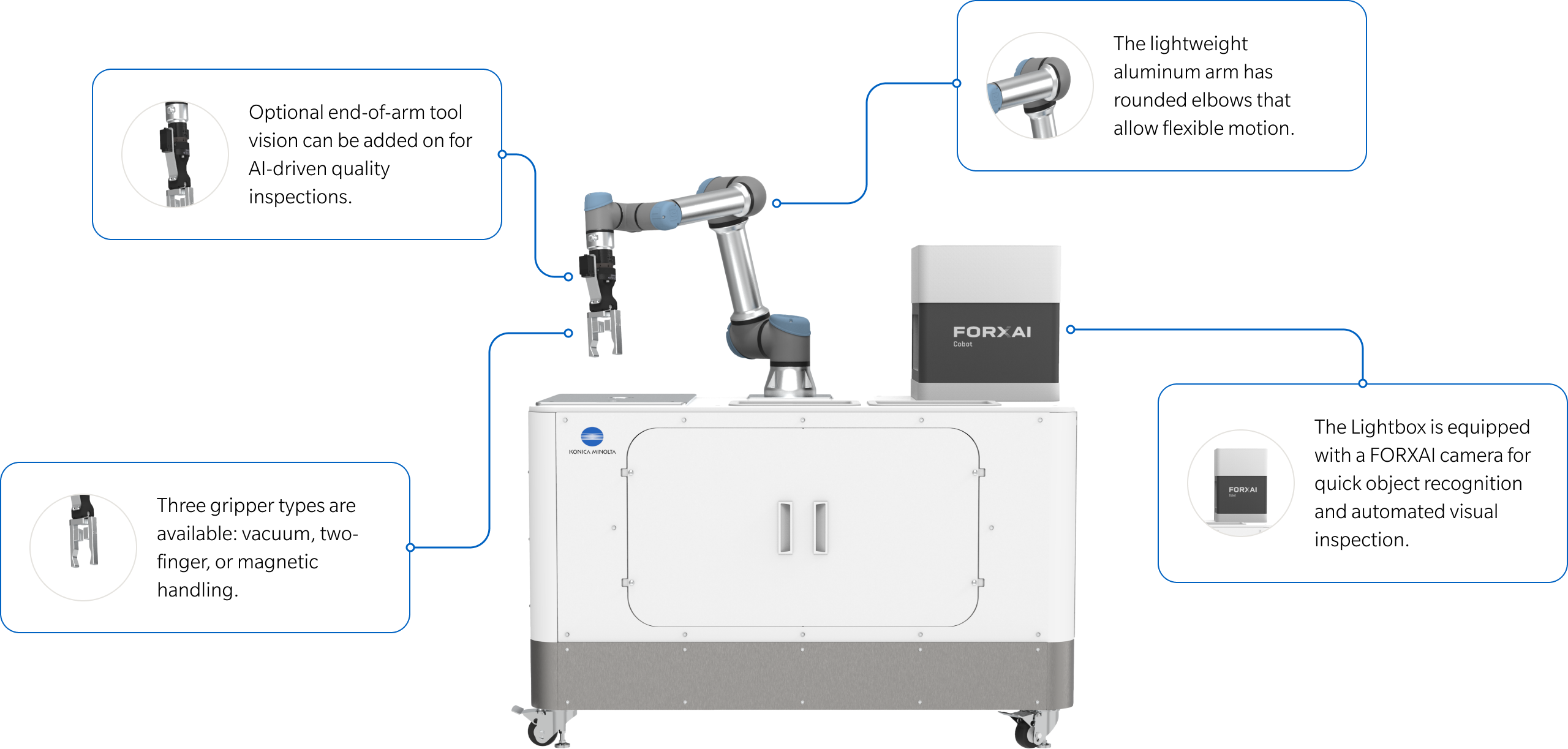

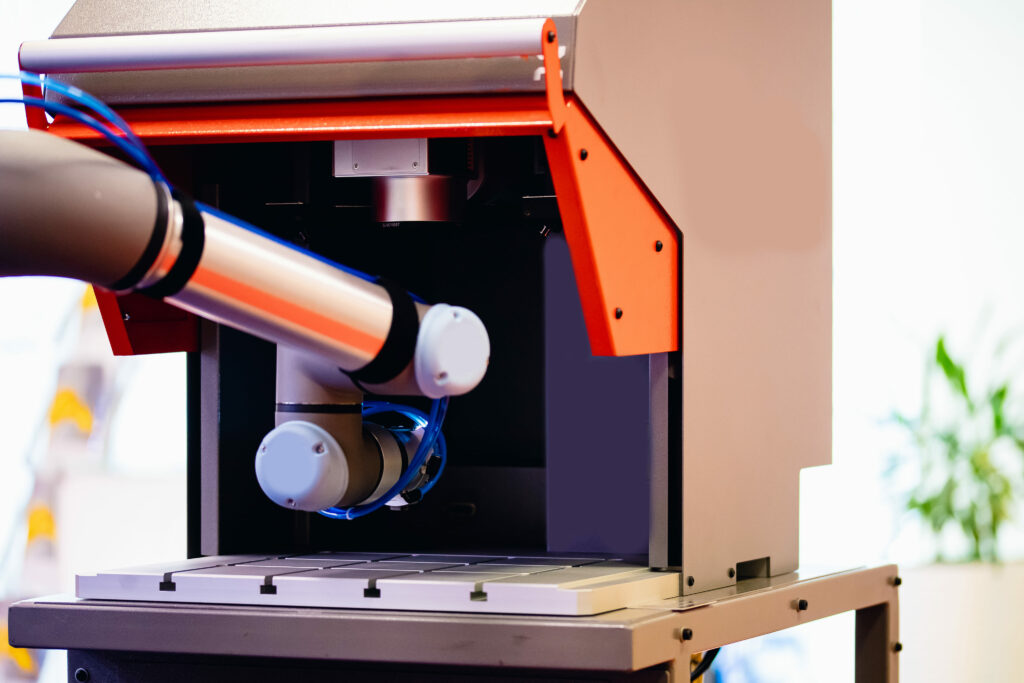

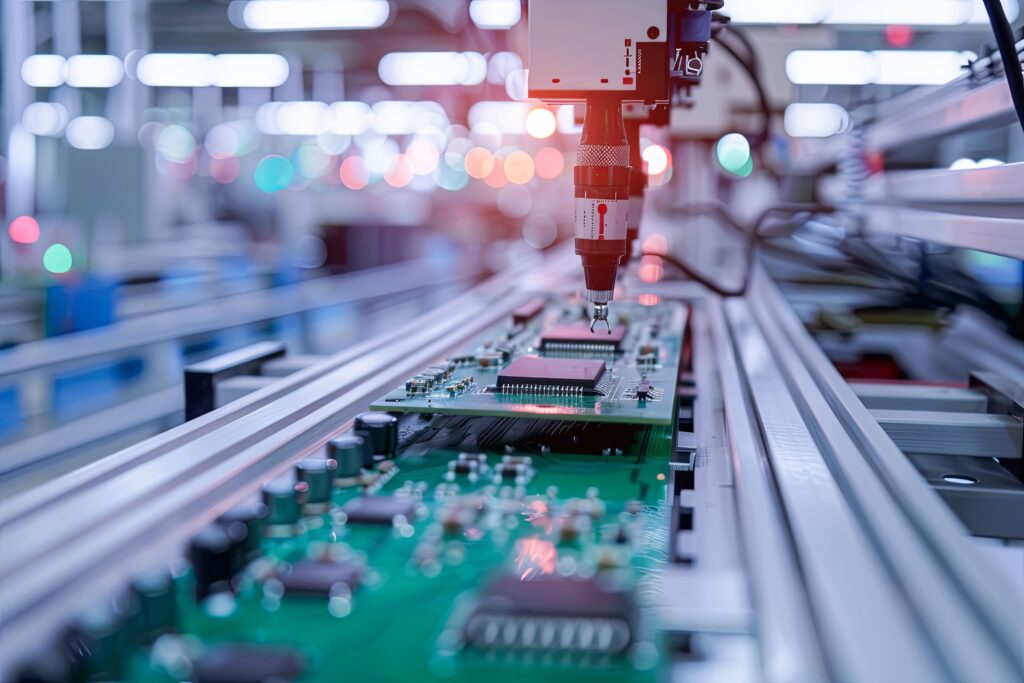

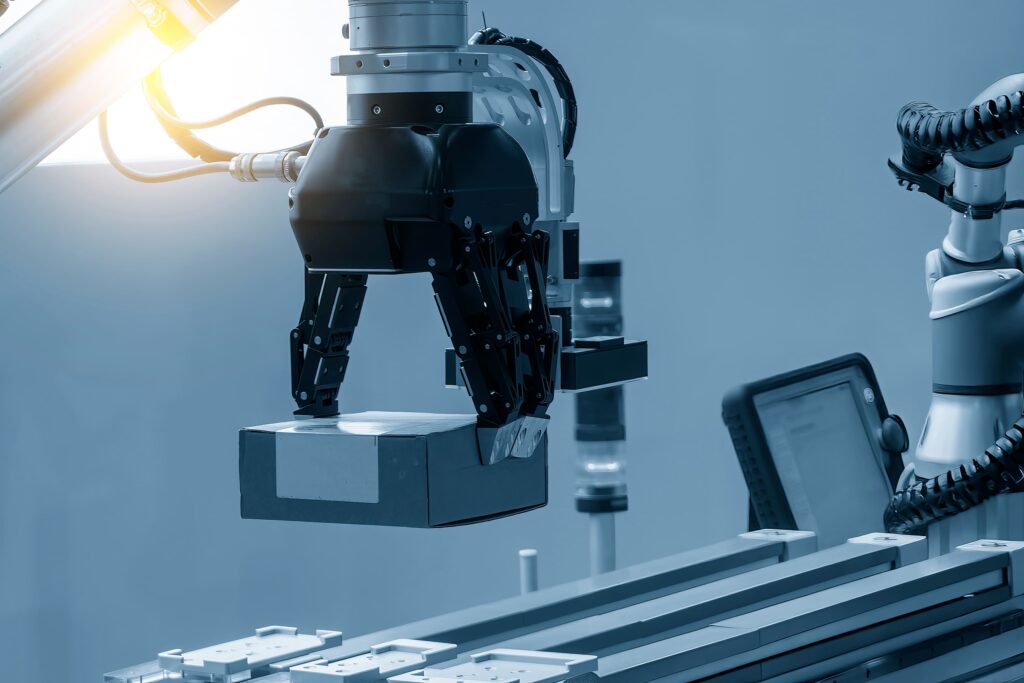

Automate and Standardize Quality Inspections

FORXAI Cobot transforms your quality control workflow by automating and standardizing inspections. This ensures every product undergoes a thorough check, reducing human error and boosting production consistency. Maintain high quality across all batches, improving customer satisfaction and meeting industry standards.