Consistent Quality

Automation ensures uniformity in product quality across production runs.

Seamless integration of advanced machine vision and AI technologies

Ability to deliver tailored A-to-Z solutions designed around customers’ unique needs

Full after-sales support and continuous improvement consultancy

Proven track record of delivering measurable results for customers

Long-standing history of industrial imaging innovation since 1873

Committed to delivering meaningful value for customers and society

Smart manufacturing involves the use of advanced technologies and data analytics to improve production processes, making them more efficient, flexible, and responsive. It integrates machines, sensors, and systems to create a connected and intelligent manufacturing environment.

A smart factory is a physical representation, where these interconnected technologies work together to optimize operations, reduce downtime, and improve product quality. In a smart factory, real-time data and automated systems enable proactive maintenance and continuous improvement.

Smart manufacturing relies heavily on the Industrial Internet of Things (IIoT) to connect machines, sensors, and devices across the production floor. IIoT solutions allow real-time data collection and analysis, providing insights that drive informed decision-making and process improvements. By leveraging IIoT, smart manufacturing achieves greater efficiency, predictive maintenance, and improved operational performance.

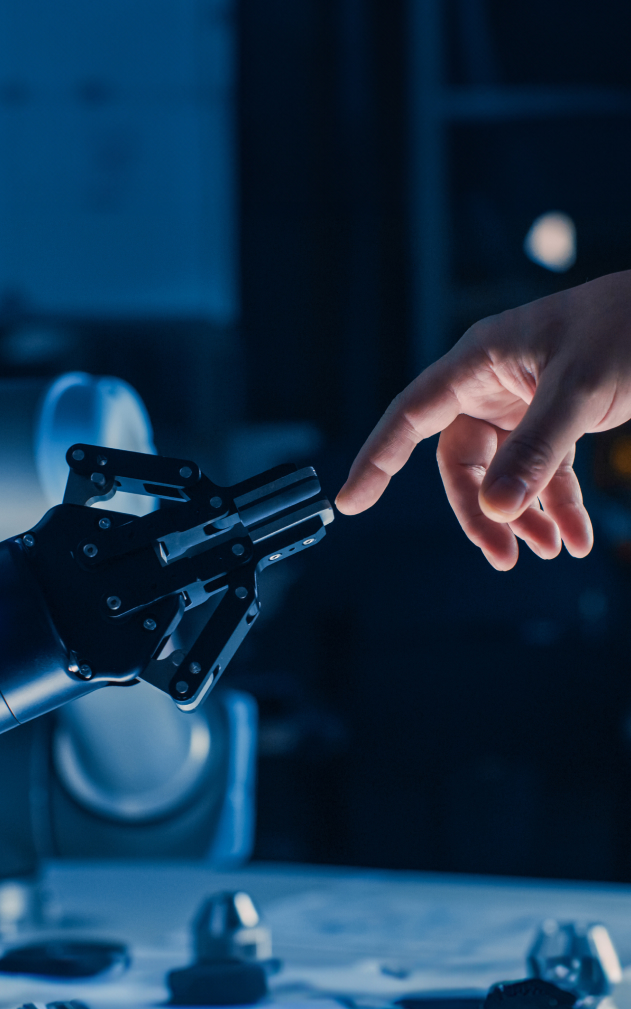

Industry 5.0 is the next phase in industrial development, focusing on the collaboration between humans and machines. It puts the well-being of workers at the center of the production process, combining human intelligence and creativity with advanced technologies like artificial intelligence (AI), robotics, and the Internet of Things (IoT). The goal of Industry 5.0 is to create a more sustainable, innovative, and worker-friendly manufacturing environment.

Industry 4.0 focuses on using digital technology to make manufacturing more efficient and productive by connecting machines and systems. It’s all about automation and data exchange. Industry 5.0 takes it a step further by emphasizing the collaboration between humans and machines. It aims to enhance human skills and create more personalized and sustainable production processes.

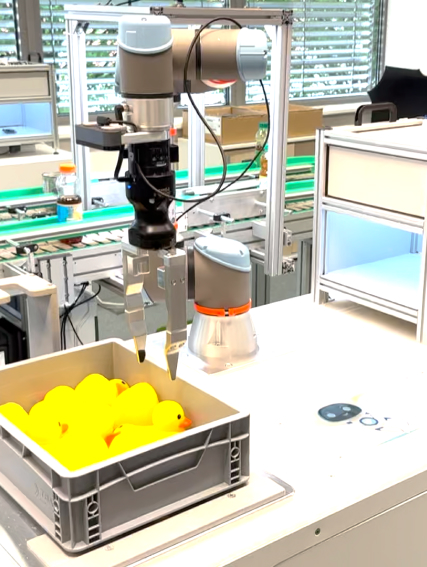

Cobots, or collaborative robots, are designed to work safely alongside humans in a shared workspace. Unlike traditional robots, which often operate in isolated environments due to safety concerns, cobots have advanced sensors and programming that allow them to safely interact with humans. They are typically used for tasks that require precision and adaptability, such as assembly, packaging, and inspection. Cobots are easy to program and can be quickly integrated into various processes, making them ideal for dynamic manufacturing environments. Traditional robots, on the other hand, require extensive programming experience and are typically used in more rigid, repetitive tasks.

Autonomous material handling involves using automated systems and vehicles to move materials within a facility without human intervention. These systems, such as Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), navigate through production areas, warehouses, and distribution centers, optimizing material flow and reducing the need for manual labor. Learn more about our AMH solutions