The end result?

Typical Robot Programming Methods

- Co-ordinates: Joint, global, tool and workpiece coordinates are common robot programming methods. Each method leverages multiple moves of each axis/joint, the robot’s overall axis system, the center point of the tool (TCP), or the coordinate system of the entire robotic cell.

- Teach pendants: Robots are manually driven, with different coordinate systems, so they can “learn” the paths and positions to take.

- Offline programming: Using CAD models of the parts to be processed or tended, offline robot programming enables experts to create a program and accompanying path data, which is ideal for complex, high-mix production environments.

Robot Programming Methods: Innovations Help Win Back Valuable Hours

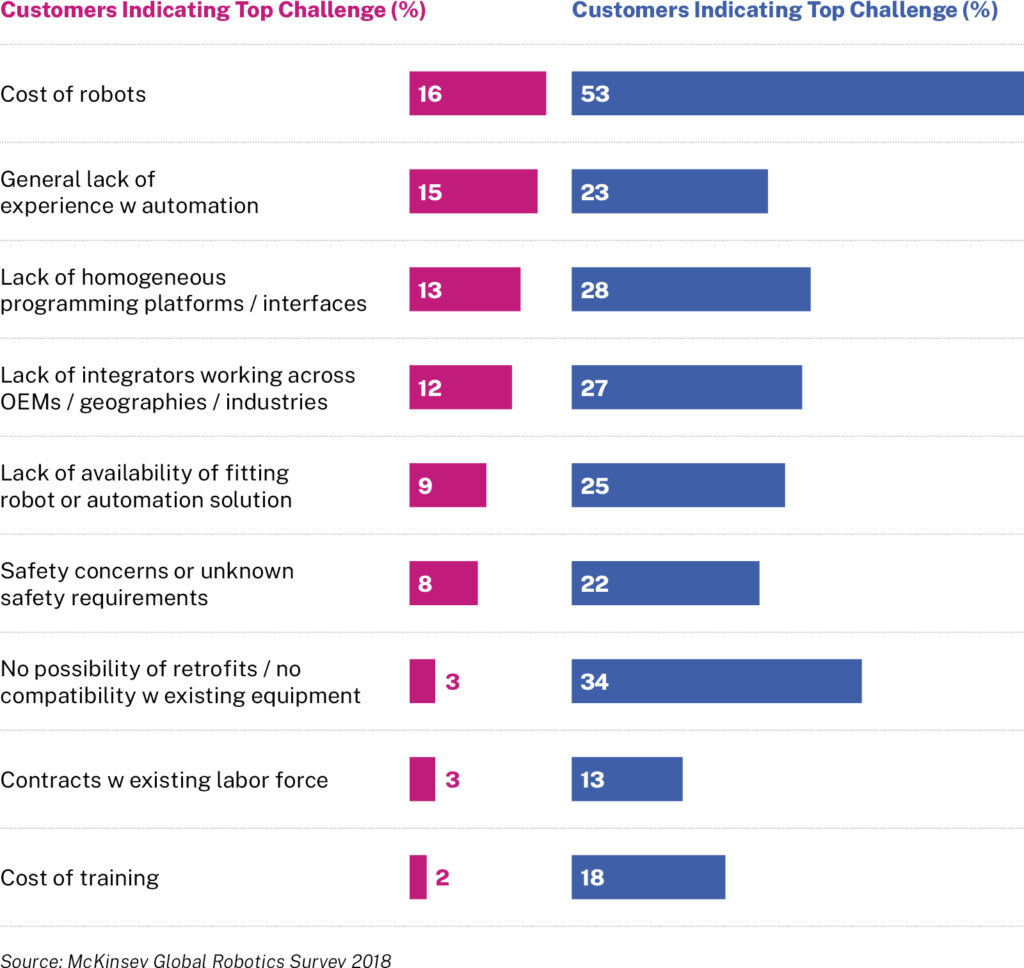

Zero-coding approaches to robot programming are surfacing as viable alternatives to the cumbersome techniques used in the past. Because they democratize automation and robotics programming, no-code robotics offer many benefits, including: Zero-coding approaches to robot programming are surfacing as viable alternatives to the cumbersome techniques used in the past. Because they democratize automation and robotics programming, no-code robotics offer many benefits, including: closing the skills gap, tackling a lack of qualified programmers, reducing training time and costs in different languages, and, inevitably, augmenting production flexibility and performance.

Common Applications in Manufacturing

- Welding: Joins metal parts with precision in automotive and heavy machinery manufacturing, ensuring strong and durable connections.

- Assembly: Constructs components with accuracy in electronics and appliance industries, enhancing product reliability.

- Painting: Applies coatings evenly in automotive and consumer goods sectors, improving aesthetics and protection.

- Material: Handling: Transfers raw materials and finished products efficiently in warehousing and logistics, optimizing workflow and reducing downtime.

Evolution of Industrial Robots

The industrial robot began with simple automation in the automotive industry and has since transformed into highly sophisticated systems across various sectors

- 1950s-1960s: The inception of basic automation, primarily in car manufacturing.

- 1970s-1980s: Introduction of programmable robots, expanding capabilities beyond mere repetition to more complex tasks

- 1990s-2000s: Advancements in robotics technology, including the integration of sensors and computer control, allowing for greater precision and flexibility.

- 2010s-Present: The era of intelligent robotics, with enhanced AI, machine learning, and connectivity features, pushing boundaries in autonomous operations.

CoboVox

Ready Robotics

Wandelbot

Wandelbot’s ergonomic input pen acts like a computer mouse to program and control industrial robots. Akin to manual procedures, the pen is used to seamlessly teach a robot or cobot its tasks for workpieces in minutes.

Nordbo

Nordbo’s Mimic joystick allows users to record, preview and optimize the movements of a robot or cobot, guiding their speeds, orientations, and paths. Nordbo is particularly conducive to craftspeople’s operations, such as pick-and-place, painting, and dispensing actions.

What’s Next

These robot programming companies are just some of the many trying to eliminate the hassles of robot programming methods. The improvements can indeed be impressive. For example, tests carried out by CoboVox showed that voice-enabled collaborative programming can decrease installation costs by over 50% and robot downtimes by 43%.

Simplified robot programming methods, such as those mentioned above, are very versatile for various industrial robot applications, such as handling, welding, assembling, and dispensing. Educational institutions and trade schools are also considering using these methods to better teach robot programming in non-programming classes.