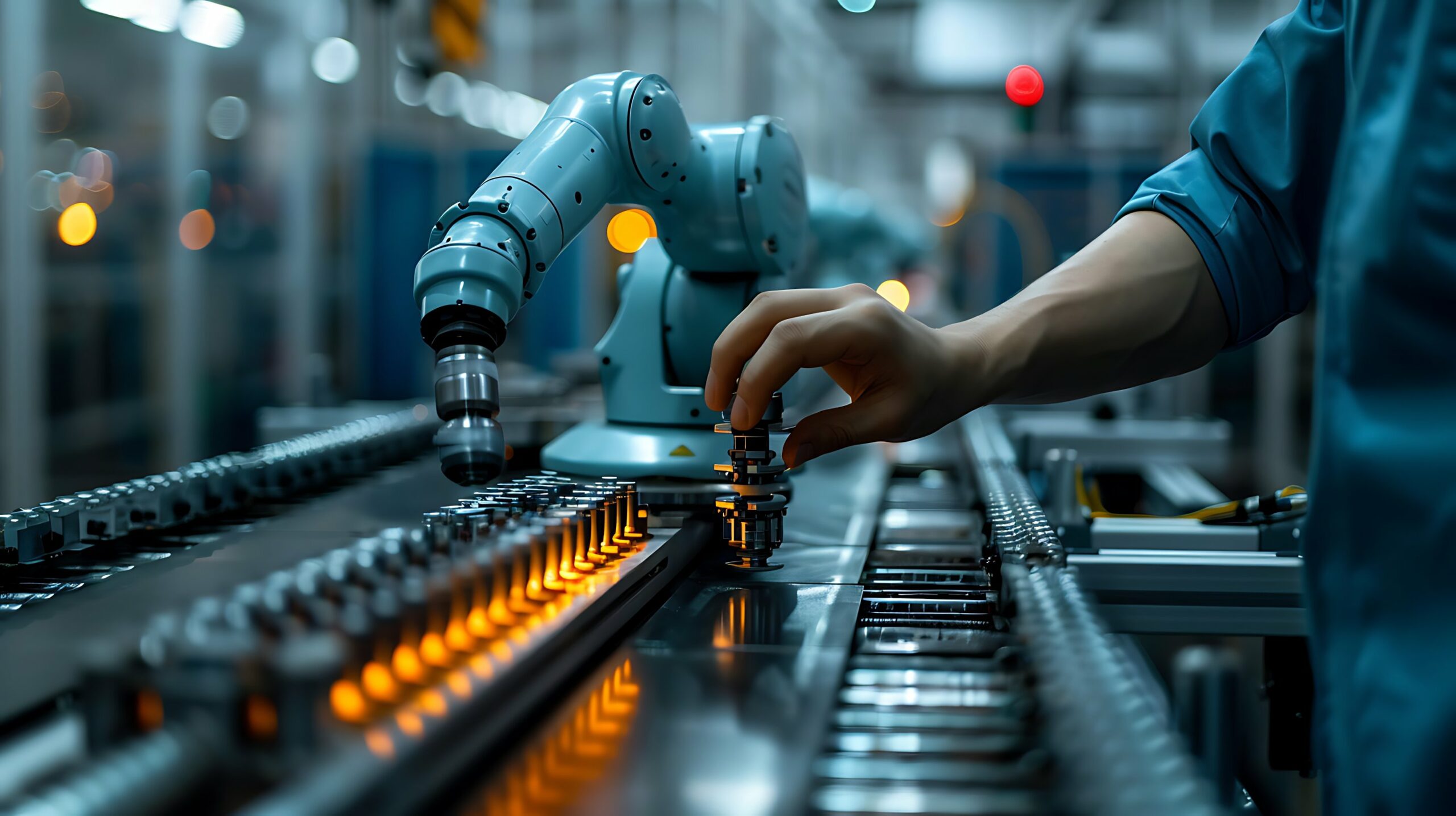

How Cobot Automation Is Changing Manufacturing

A recent study shows that the global cobot market is expected to grow at a compound annual growth rate (CAGR) of 45.4% from 2021 to 2026. This statistic underscores a significant trend: companies increasingly recognize cobots’ value in their operations.

What is Cobot Automation

Collaborative Robot Operation Modes

-

Power and force limiting cobotsPower and force limiting cobots are often what most people envision when they think of collaborative robots. They are designed to sense contact with humans and immediately cease operation, eliminating the need for safety barriers.This feature makes them ideal for smaller applications where frequent human-robot interaction occurs. Their safety mechanisms allow for close collaboration without compromising worker safety.

-

Safety rated and monitored stop cobotsSafety-rated and monitored stop cobots are equipped with systems that detect when a person enters a designated area. Upon detection, the cobot stops operating until the person leaves the shared workspace. This eliminates the need to restart the cobot manually.

These cobots are particularly useful in environments where human-robot interaction is infrequent, but occasional access to the robot’s workspace is required.

-

Speed and separation cobots (Fenceless Cobots)Speed and separation cobots, also known as “fenceless” cobots, are designed to provide easy access for humans while maintaining safety. Safety laser area scanners create zones around the robot’s workspace.When a person approaches, the robot slows down and stops if the person gets too close. Once the person moves away, the robot resumes its normal operating speed.This mode is ideal for applications where minimal human interaction is needed, but access to the robot’s workspace must be safe and straightforward.

-

Hand guiding cobotsHand guiding cobots feature a safety-rated device attached to the end of the robot’s arm, allowing a person to manually guide or move the robot. This mode is particularly useful for quickly programming new robot paths and positions by hand.It is ideal for mobile applications where the cobots need to move between stations and require frequent reprogramming for different tasks. Hand guiding makes it easy to adapt the cobot to new jobs without extensive downtime for reprogramming.

Why Should You Invest in Collaborative Robots

Cobots’ ease of use and ability to perform a variety of tasks makes them a compelling investment for modern manufacturers.

Here are four reasons why you should consider adopting cobots into your processes.

Collaborative Robot Operation Modes

- Improved safety and reduced workplace injuries

Cobots are designed with advanced safety features, such as force-limiting sensors and collision detection, which allow them to operate safely alongside human workers.

Case Study: At Bajaj Auto, the implementation of cobots led to a safer working environment and improved ergonomics. The cobots were used for repetitive tasks like assembly and mial handling, reducing the strain on workers and lowering workplace injuries. - Increased Productivity and Efficiency

Cobots can perform repetitive and precise tasks consistently without fatigue, leading to higher productivity and efficiency. They can operate 24/7, ensuring continuous production and reducing downtime.

Data: AIM Processing, a company specializing in plastic injection molding, saw a remarkable 400% increase in productivity after integrating cobots into their operations. The cobots handled tasks such as machine tending and quality inspection, which allowed human workers to focus on more complex and value-added activities - Cost-Effective and Quick ROI

Cobots are generally more affordable than traditional industrial robots and offer quicker returns on investment. Their lower initial cost, combined with reduced setup and maintenance expenses, makes them an attractive option for manufacturers of all sizes.

Proof: A case study from Engineering.com highlights how Indiana-based Task Force Tips, a manufacturer of firefighting equipment, saw a fast ROI by integrating vision-guided cobots into their CNC machining cells.

The cobots helped streamline operations and reduce labor costs, leading to significant financial benefits.

Additionally, Automate.org reports that the positive cash flow from robotic systems can turn a $250,000 investment into approximately $1.5 million over the robot’s service life, primarily through labor savings and productivity gains. - Flexibility and Adaptability

Cobots are versatile and can be reprogrammed to perform various tasks, from assembly and welding to packaging and inspection. This flexibility allows manufacturers to quickly adapt to changing production needs without significant downtime or additional costs.

Case study: Hofmann Glastechnik has eight UR cobots supporting glass apparatus manufacturing. The cobots load several glass lathes and are actively involved in the forming of glass. Their consistent operation stabilizes production processes, increases product quality, and ensures reliable delivery capability.

Implementing cobots resulted in a 25% increase in productivity, with the cobots paying for themselves in less than 12 months

Collaborative Robots vs. Traditional Industrial Robots

What Are The Different Cobot Applications

- Assembly:Cobots excel in assembly tasks due to their precision and ease of programming. They perform tasks such as screwing, fitting, and positioning components with consistency, reducing errors.

- Quality inspection: Cobots can automate visual quality inspections, including scratch, mar, and abrasion resistance tests. This system allows testers to focus on more value-adding tasks. CoboSense streamlines surface quality inspections. It’s flexible and scalable and can be customized to testing processes using different plug & play modules and end-of-arm tools.

- Machine tending: Cobots can load and unload machines, handle materials, and manage production processes.

- Material handling: Cobots can combine quality assurance with AI and machine vision for tasks like assembly, bin picking, organizing, sorting, packaging, etc. In a logistics center, FORXAI Cobot assists with sorting packages and placing them on conveyor belts, speeding up the sorting process and reducing labor costs.

- Welding: Cobots are ideal for welding tasks due to their ability to perform consistent and high-quality welds.

- Palletizing: Cobots easily handle palletizing tasks, reducing the physical strain on workers.

Current Market Needs & Future of Cobot Automation

FAQ

What makes a cobot safe to use?

Cobots are equipped with advanced sensors and safety features, such as force-limiting technology and collision detection, which allow them to operate safely alongside human workers without the need for safety cages.

Are cobots more efficient than humans?

Cobots can perform repetitive tasks with high precision and consistency, leading to increased efficiency and productivity compared to manual labor. However, their efficiency complements human workers rather than entirely replacing them

Can I customize cobots as per my needs?

Yes, cobots are highly versatile and can be customized with different end effectors, programming, and accessories to fit specific tasks and industry requirements.

What are some of the best cobot companies in Europe?

Prominent cobot companies in Europe include Universal Robots, Fanuc, Festo, and ABB. These companies are known for their innovative solutions and reliable cobot technologies.

Konica Minolta Business Solutions Europe is a Certified System Integrator of Universal Robots. Depending on the customer’s needs, we can also integrate different cobot/robot brands. Talk to our consultants about your project.

Will cobots replace some jobs?

While cobots may take over repetitive and hazardous tasks, they are designed to work alongside humans, often leading to job transformation and creation rather than replacement. Cobots can improve job satisfaction and create opportunities for higher-value tasks.

Are cobots AI-enabled?

Many cobots incorporate AI and machine learning technologies to improve their capabilities. For example, FORXAI Cobot combines AI with machine vision for advanced quality control and material handling tasks.